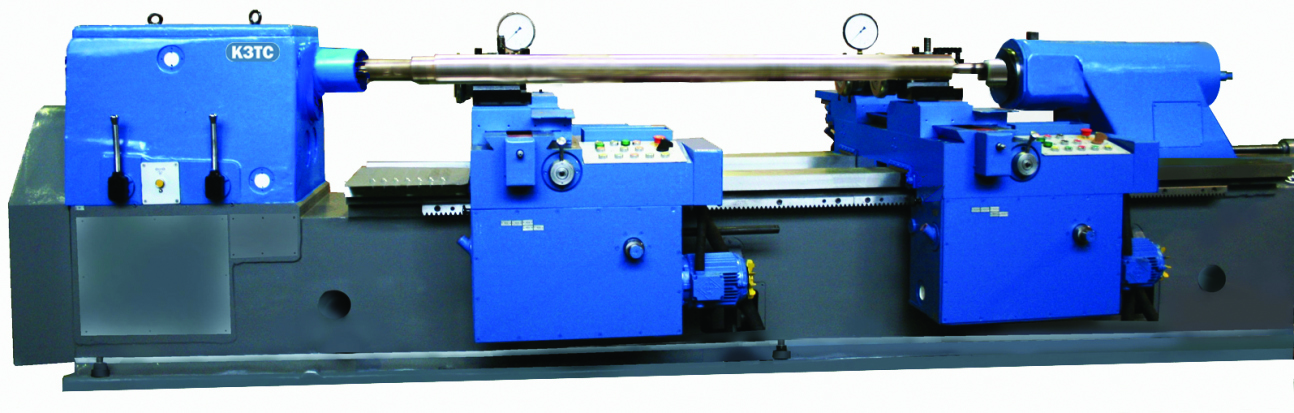

TURNING ROLLING MACHINE MODEL KJ1842.02

For turning and roll- hardening journals and pre-hub mounting and hub mounting axle portions of wheel- sets of diesel, electric locomotives- and cars.

Principal users of the machines:

- rail way transport

- transport machine building

- defense industry

- car-wheel shops

- locomotive and car repair plants

100 machines produced.

DESIGN FEATURES:

Machining axle journals for wheel-set pre-hub and hub portions are performed simultaneously by LH and RH carriages

Machine bed has three flat guide ways.

RH head with rotating center, head quill moves by hydraulic unit only.

Machine is provided with two carriages.

Two-position swing holders for cutters and rollers are located on front slide.

Roller holders only are mounted on back slide. Apron mechanisms transmit different forward movements to carriage at turning and rolling journals for wheel pre-hub and hub portions of wheel-sets. Hydraulic system of carriages with original pressure regulator provides control of cross slides movement and rollers pressure on axle.

The axle is installed in the centers of head-and RH-stocks by shop lifting-transport means.

MAIN TECHNICAL SPECIFICATIONS:

| Параметр | Значення |

|---|---|

| Centers height, mm | 320 |

| Max. distance between centers, mm | 2 700 |

| Diameter of journal to be machined, mm | 90–240 |

| Number reducer speeds steps, pc | 6 |

| Axle rotation speeds, rpm | 58; 78; 120; 160; 216; 335 |

| Number of carriages (double type), pc | 2 |

| Longitudinal feeds, mm/min | 56; 78; 115; 162 |

| Carriage rapid speed, m/min | 2,6 |

| Main drive motor power, kW | 11 |

| Machine overall dimensions: | |

| - length, mm | 5 085 |

| - width, mm | 2 900 |

| - height, mm | 1 365 |