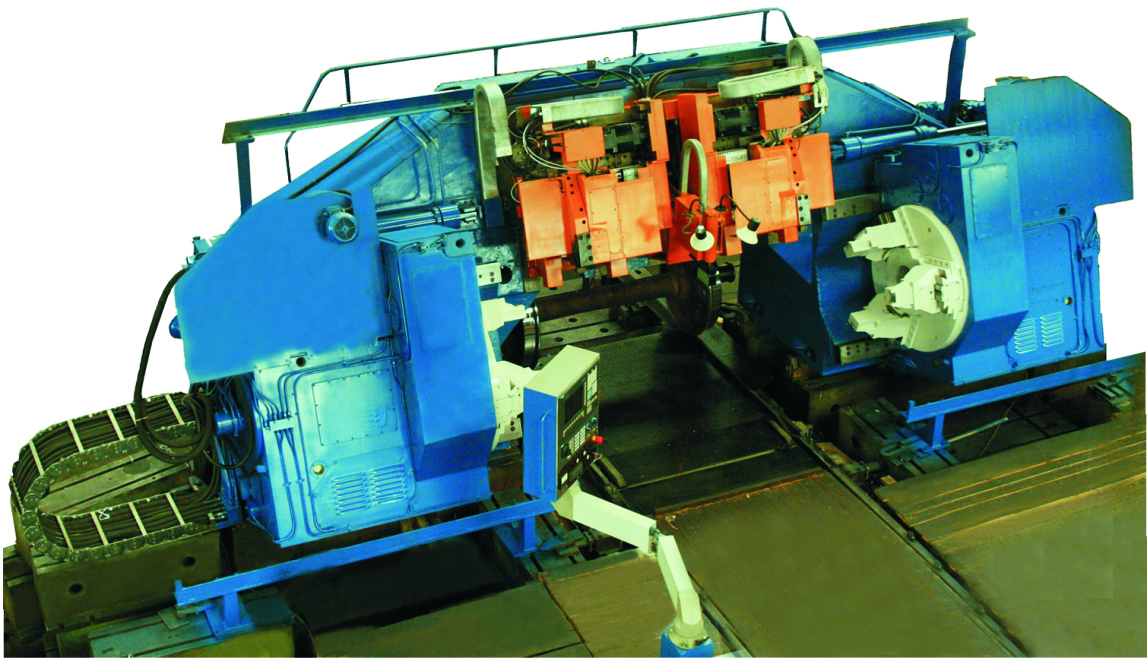

CNC WHEEL TURNING LATHE MODEL 1K836F3

This machine is designed for machining wheel-sets for rail road rolling stock and cars with dismounted axle boxes and reducer bodies.

Principal users of the machine:

- rail way transport

- transport machine building

- defense industry

- car-wheel shops

- locomotive and car repair plants

10 machines produced.

DESIGN FEATURES:

Portal configuration provides sufficient rigidity and enables mounting the machine in technological transfer line for repavir of wheel-sets.

Automation of most technological operations and CNC – system provide high accuracy productivity of machining , increases permissible number of restoration returnings and performance resource of wheel-set.

MAIN TECHNICAL SPECIFICATIONS:

| Parametr | Value |

|---|---|

| Dimensions of wheel-sets: | |

| - Diameter on tread, mm | 800 – 1 250 |

| - Axle length, mm | 2 020 – 2 550 |

| Max. weight of wheel- sets, kg | 4 000 |

| Rail way gauge, mm | 1 520 |

| Wheel rim width, mm | 130 – 140 |

| Max. cross section of cutter, mm | 50 х 55 |

| Discreteness of displacements, micron | 1 |

| Number of controllable coordinate axes, pc | 4 |

| Number of simultaneously controllable coordinate axes, pc | 4 |

| Carriages operation feeds: | |

| - longitudinal, mm/min | 1 – 50 |

| - traverse, mm/min | 1 – 50 |

| Speed of setting longitudinal and cross carriage movements, m/min | 3 |

| Number of faceplates rotation speed steps | безступінчасте |

| Faceplates rotation speeds, rpm | 5 – 30 |

| Max. torque on spindle, KNM | 26 |

| Jack lift speed, mm/min | 1 100 |