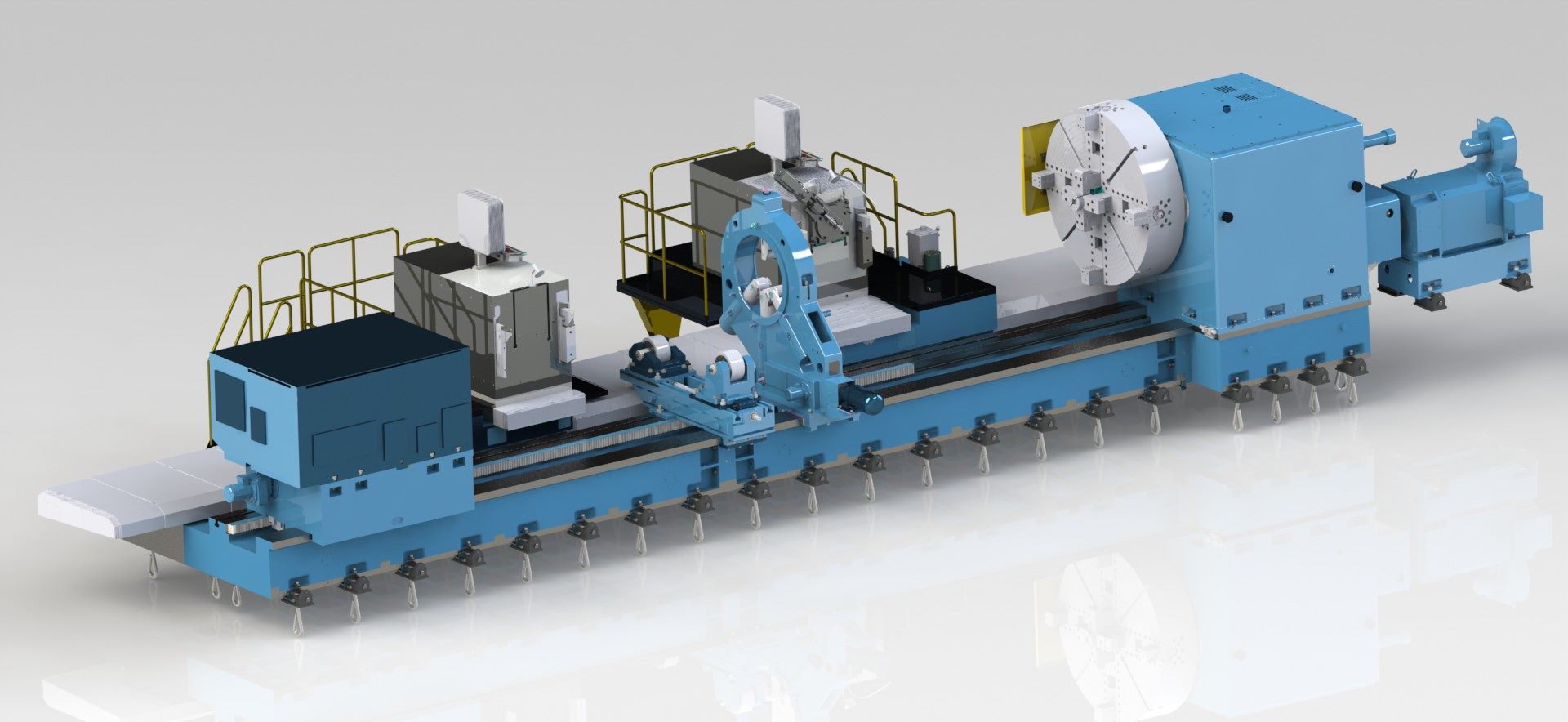

Machine tool 1К675.01Ф3х8000

In December 2019, a high-performance roll turning machine model 1K675.01F3x8000 manufactured by KZVV was put into operation. The machine is designed for turning sheet and heavy-gauge rolls, as well as for barrel cutting of rhombic and lentil rolls.

It is noteworthy that the 1K675.01F3x8000 can machine rolls made of high-strength cast iron, high-speed and zeutectoid steels with a barrel hardness of up to 90 HSD.

The machine is equipped with two turning slides, each of which has two side cutter holders for machining rolls using the latest generation of SIEMENS SINUMERIK 840Dsl CNC programme.

This equipment is unique because it combines the functions of roughing and finishing machining. The presence of two calipers and their specially developed design made it possible to achieve a productivity in terms of processing time per roll that has no analogues in the world. The closest competitors process such rolls in a time that is four times faster than the KZVV machine.

The machine weighs 132 tonnes.

The maximum weight of a workpiece is 70 tonnes.

The maximum diameter of the workpiece is 1850 mm;

The 1K675.01F3x8000 rolling machine manufactured by PJSC ‘KZVV’ meets all modern machine tool standards.